Use the Gouge avoidance page to determine what happens to the toolpath when a surface prevents profiling at the lowest position.

Gouge check — Select this option so PartMaker checks the toolpath to see if any part of it gouges or deselect to turn gouge checking off.

Strategy —Select a strategy to determine how the toolpath behaves when another surface would cause gouging.

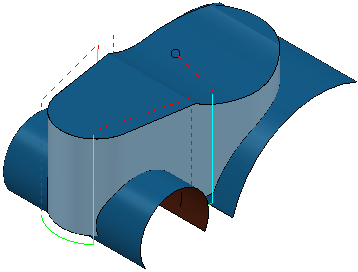

- Lift — Select so PartMaker tries to machine at the lowest position. If it can't machine at the lowest position the toolpath segments are removed.

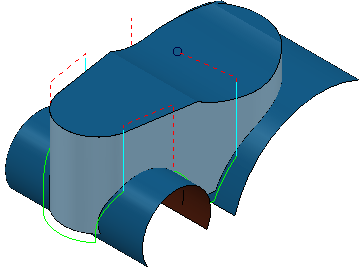

- Trace — Select so PartMaker tries to machine at the lowest position. If it can't machine at the lowest position, the toolpath is raised as little as possible until it reaches a position at which it can machine.

Degouge tolerance — Enter the maximum distance, normal to the surface, that the toolpath can move to find a safe position. If gouges greater than this value are detected, then the tool is lifted axially to avoid the gouge.

Note: Gouge avoidance moves the tool along the tool axis. Degouging moves the tool along the surface normal.