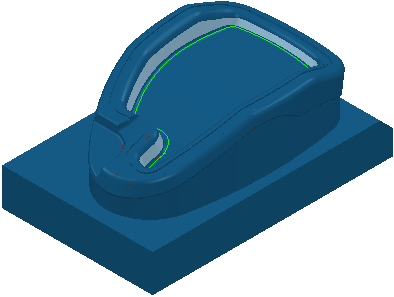

Swarf finishing cuts with the side of the tool and only works on developable surfaces because the tool must be in contact with the surface for the whole cutting depth.

For a tool to swarf cut, it has to be able to have contact with the surface at all points along the cutting edge of the tool. For non-developable surfaces, PartMaker will always leave material on or produce fragmented toolpaths (rather than gouge). This means that you need to look at parts carefully before trying to swarf cut them. It may be that rotating the part (cutting from the side rather than the top of an aerofoil blade) may produce the desired result. Swarf machining makes every attempt to machine the selected swarfing surfaces, but you may have to edit the swarf milling options to obtain the best machining results.

This strategy does not support Boundary or other curve types.

The availability of this strategy depends on the machining function you are using.

The Swarf finishing strategy is available for the following machining functions:

PartMaker/SwissCAM and PartMaker/Turn-Mill

- Mill 5-Axis Plane

- Mill ZY Plane

PartMaker/Mill

- Mill 5-Axis Plane

- Mill 4-Axis Plane

On the Strategy dialog, the following pages are available for the Swarf finishing strategy:

- Swarf finishing — The main page used to define a swarf toolpath.

- Position — Settings todetermine the location of the toolpath.

- Gouge avoidance — Settings to determine what happens to the toolpath when a surface prevents machining at the lowest position.

- Multiple cuts — Settings to enable multiple passes down the tool axis.

- High speed — Settings to improve the smoothness of the toolpath.

The remaining pages are common toolpath creation controls.