Model area clearance creates a toolpath by slicing the model at specified heights and then creating a Raster, Offset or Vortex pass at each height.

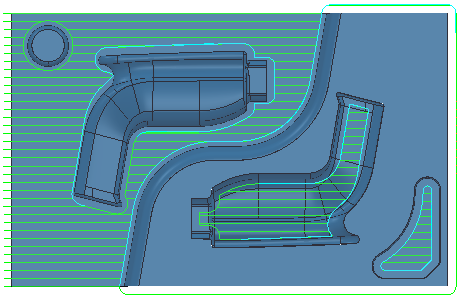

- A Raster style toolpath creates cutting moves at a specified angle to either the X or Y axis. Raster toolpaths are often used on open parts.

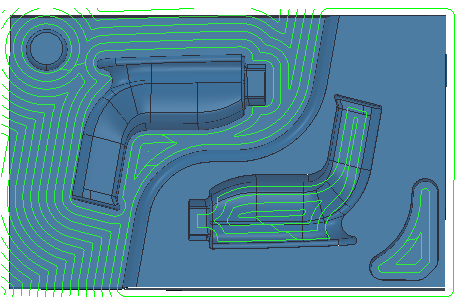

- An Offset model / Offset all style toolpath creates cutting moves by offsetting the model or block. These work well in the bottom of pockets and are good for high-speed machining.

- A Vortex style toolpath produces an offset toolpath which never exceeds the maximum tool engagement angle for optimum machining. As the tool approaches the maximum engagement angle, the toolpath changes to a trochoidal path to avoid tool overload. This works well for solid carbide tools.

This strategy rapidly removes material from a 3D part, while following the part and keeping air moves to a minimum, which minimizes wear to both the tooling and the machine.

This strategy supports Boundary curves.

The availability of this strategy depends on the machining function you are using.

The Model area clearance strategy is available for the following machining functions:

PartMaker/SwissCAM and PartMaker/Turn-Mill

- Mill XY Plane

- Mill 5-Axis Plane

- Mill ZY Plane

- Mill End, Polar

PartMaker/Mill

- Mill XY Plane

- Mill 5-Axis Plane

- Mill 4-Axis Plane

On the Strategy dialog, the following pages are available for the Model area clearance strategy:

- Model area clearance — The main page used to choose the area clearance styles and associated settings.

- Raster — Settings to define a raster area clearance style. This is available when you select a Style of Raster on the main page.

- Offset — Settings to define offset area clearance styles. This is available when you select a Style of Offset model or Offset all on the main page.

- Vortex — Settings to define a Vortex area clearance style. This page is available when you select a Style of Vortex on the main page.

- Step cutting — Settings to define in-line rest roughing. This minimizes terracing when creating area clearance toolpaths with a large stepdown.

- Rest — Settings for rest machining.

- Wall finishing — Settings to perform a Final stepover that differs from the normal stepover.

- Unsafe segment removal — Settings to remove small toolpath segments.

- Flat machining — Settings to machine flat areas on the model.

- High speed — Settings for various smoothing options to avoid sharp changes in tool direction when high-speed machining.

- Order — Settings to control the order of machining.

- Approach — Settings to control how the tool approaches the toolpath.

The remaining pages are common toolpath creation controls.

Tip: Use the Surfacing Defaults dialog to specify the default settings for Advanced Surface Machining toolpaths.