Material Stress Dependence, Alternate Form

Description: Specifies stress-dependent material properties for use in nonlinear analysis. This entry is used if a MAT1 entry is specified with the same MID.

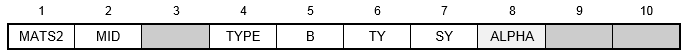

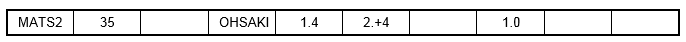

Format:

Example:

| Field | Definition | Type | Default |

|---|---|---|---|

| MID | Identification number of a MAT1 entry. | Integer > 0 | Required |

| TYPE | Type of material nonlinearity, one of the following character variables: OHSAKI for hysteresis soil plasticity or RAMBERG for deformation plasticity. See Remarks. | Character | Required |

| B | Exponent. | Real > 0.0 | Required |

| TY | Initial tensile yield strength. | Real > 0.0 | See Remark 3 |

| SY | Initial shear yield strength. | Real > 0.0 | See Remark 3 |

| ALPHA | Initial yield offset. | Real | 0.0 |

Remarks:

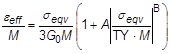

- If TYPE = OHSAKI, B is a soil type factor (1.6 for sand and 1.4 for clay) and TY is the initial tensile yield strength. If specified, ALPHA is ignored in this case. The constitutive relationship is given by:

where,

is the initial shear modulus

is the initial shear modulus

is 1 for initial loading and 2 for unloading and reloading

is 1 for initial loading and 2 for unloading and reloading

is the effective strain

is the effective strain

is the equivalent stress

is the equivalent stress

and,

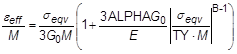

- If TYPE = RAMBERG, B is a hardening exponent (normally, B > 5), TY is the initial tensile yield strength, and ALPHA is the initial yield offset. The constitutive relationship is given by:

where,

is the reference elasticity modulus

is the reference elasticity modulus

is the initial shear modulus

is the initial shear modulus

is 1 for initial loading and 2 for unloading and reloading

is 1 for initial loading and 2 for unloading and reloading

is the effective strain

is the effective strain

is the equivalent stress

is the equivalent stress

- The relation between initial tensile yield strength and initial shear yield strength is given from the von Mises yield criterion:

. Either TY or SY must be given. When both are given, SY will be ignored.

. Either TY or SY must be given. When both are given, SY will be ignored.

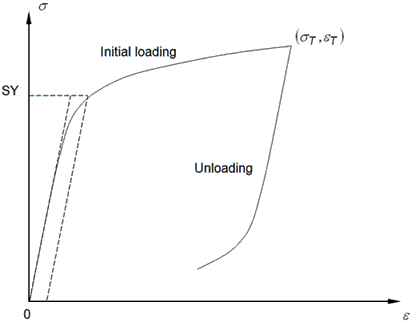

- When the loading direction changes, the effective stress and strain are calculated with respect to the last stress and strain locations of the previous load step (turning stress

, and strain

, and strain

). See Figure 1.

). See Figure 1.

- Material nonlinear behavior requires a nonlinear solution.

Figure 1. Stress-Strain Curve Definition for MATS2 Material